Welding is an important skill across numerous sectors, and the selection of correct welding rod makes a significant difference especially while welding thin metal. Regardless of whether you’re a professional welder or working as a hobbyist, using the appropriate welding rod will help create clean welds, stronger joints, and less distortion. For example, the needs of welding thin metal are different than heavy penetrative welds; lower heat input, lower amperage, and an electrode to give smooth arc stability. With the right rod, you can also make your aesthetic finish better by avoiding parts warping and burn-through, which are common issues to tackle on metals such as sheet aluminum, mild steel, or stainless steel.

There are various welding rods available in the market for every types of metals and applications. The choice for thin metals can include the welding type (TIG, Stick, or MIG), the aspects of the metal and the strength of the weld that is needed. In this article, we will take a closer look at the features, specifications, and benefits of some of the best welding rods available for use on thin metals. From all useful perspectives of the welding rods, we will be evaluating its measures, usability, and how these can give you perfect-looking results while you work on delicate materials. From aluminum to stainless steel and mild steel rods, you’ll find it here.

1. ARCCAPTAIN Aluminum TIG Welding Rods

ARCCAPTAIN Aluminum TIG Welding Rods It is perfect to weld thin sheets. This rod is also excellent for TIG (Tungsten Inert Gas) welding, that is a method great for working with thin materials, as it provides control and precision. The rod is a 4043 aluminum alloy composite, which is a tried and true aluminum welding material offering strong welds and good crack resistance. You are suited in having it particularly useful when using thin aluminum (0.040″ to 0.125″), as it requires low heat to be inputted than the rest of the welding applications.It has a melting point of about 1,200°F (649°C), meaning this ARCCAPTAIN rod can generate smooth welds with less spatter, and allows for a smaller margin to work with when working with thin films allowing you almost complete prevention of burnthrough. 3/32″ in diameter because it allows you greater control for thin metals so less overall heat can be applied without burning through the base material. This rod is also suitable for both AC and DC current, offering a wide range of application to different welding machines.

Pros:

- Due to less heat input, there is reduced chances of warping or burn-through.

- It provides clean, smooth welds with minimal spatter.

- Good for use on thin aluminum applications like automotive or sheet metal work.

Cons:

- Occasional rust formation may occur

2. YESWELDER E7018 3/32 Welding Rod

The YESWELDER E7018 3/32 welding rod is a stick electrode that works great at welding medium steel, low alloy steels, and thin steel. Ever since, this rod became known for its smooth forward arc and easy-to-make weld bead, making it great for welding thin metals. Because the E7018 is low hydrogen, it prevents hydrogen-induced cracking to a great degree, leading to stronger and longer-lasting welds for thin materials.

With a 3/32″ diameter, the current input is lower, and it is better for thinner metals (sheet steel), which tend to warp or burn through easily. The flux coating on the rod produces a stable arc that means less pesky spatter, which comes in handy when there’s thin metal and you need precision. It is very crack-resistant, so it is great for projects where the weld joint is under stress.

Pros:

- Ideal for thin steel welding with low splashing.

- Low-hydrogen electrode enhances tensile and crack resistance.

- High strength, long lasting welds for critical application.

Con:

- Minor discoloration in the flux coating can occur

3. SÜA — E4043 Aluminum Stick Electrode Rod

The SÜA Aluminum E4043 Stick Electrode Rod is a versatile rod that works well for thin aluminum materials. This is a great performing electrode that is popular with both entry-level and professional welders that have a strong presence in the market. E4043: A general class of alloy, popular for its resistance to cracking, making it suitable for welding thin aluminum sheets and sections. This allows a narrow heat zone and better weld pool control with less risk of burn-through of thin materials for a reasonably smooth weld bead.

The SÜA rod at 3/32″ diameter, is ideal for thin aluminum, and allow optimal control of the weld. Designed for AC power, this rod works with most TIG welders. This rod produces minimal porosity with a clean, polished finish. Aluminum is also an excellent balance of strength versus flexibility, making it perfect for light and heavy-duty aluminum applications.

Pros:

- Allows for low heat input to minimize chances of burn-through

- Delivers smooth, steady welds on thin aluminum sheets.

- Fair fluidity and excellent crack resistance.

Con:

- Better for thin aluminum; may not work on thicker stuff.

4. TOOLIOM E6013 Welding Rod

TOOLIOM E6013 welding rod is a popular option for those who want to weld thin metals, especially mild steel, carbon steel, and stainless steel. Easy arc-starting and minimal spatter make this electrode ideal for the novice and experienced welder alike. Providing a stable arc, the 6013 series is also suitable for welding thin materials with burn thru and warpage concerns. Used for thin sheet metal and also to avoid overheating. That composition offers smooth, consistent weld beads, which is ideal for a high-quality finish in automotive or appliance repair. It’s also resistant to oxidation, which can be a key consideration when working with thin metals that will be exposed to the elements. The TOOLIOM E6013 welds really well with thin steel sections, offering strong, clean welds.

Pros:

- A stable arc which is easy to use, good for first-timers.

- Applicable to thin steel without burn-through.

- Little spatter, even welds and shiny polish.

Con:

- Traditional temporary burns can be cleaned off easily

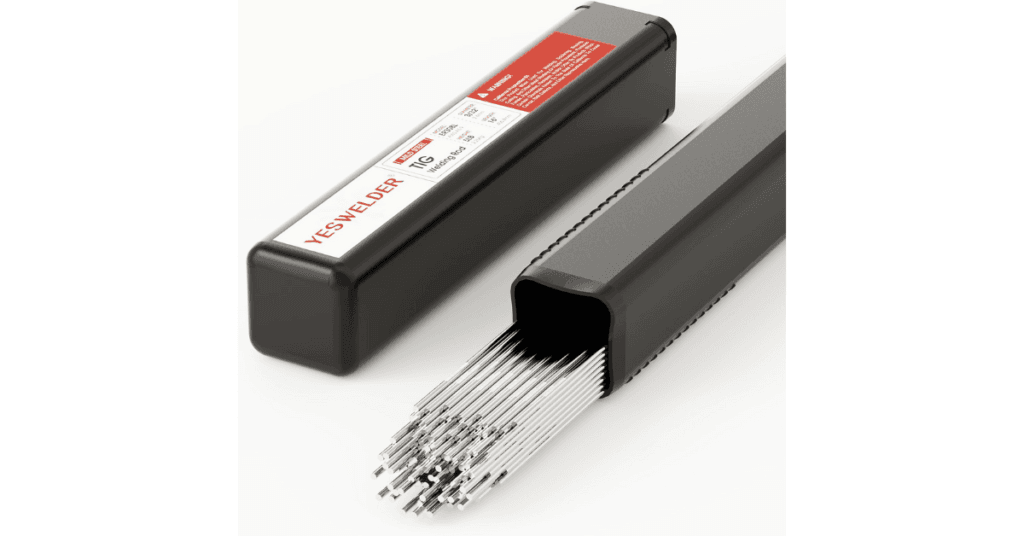

5. YESWELDER Stainless Steel TIG Welding Rods

YESWELDER Stainless Steel TIG Welding Rod is best choice for thin stainless steel applications. This welding rod is made specially for TIG welding and is ideal for welding thin sections of stainless steel. This rod has a precise alloy composition resulting in very high corrosion resistance. YESWELDER made this rod with a 1/16″ diameter, which allows the best control and most reduction of heat input. Mild spatter and clean finish are provided by the smooth arc stability, while the superior weld strength is achieved by the rod. The 308L alloy content makes it suitable for thin stainless steel materials, resulting in good corrosion resistance and high durability.

Pros:

- Suitable for welding thin stainless steel with low heat input.

- Offer great corrosion resistance with a long-lasting finish.

- Stable arc smoothness to enable clean, quality welds.

Con:

- A little flux residue left on the weld can usually be removed

How to Choose Best Welding Rod for Thin Metal?

The best welding rod for thin metal varies based on the type of metal you’re using, the welding process (TIG, MIG, or Stick), and the metal’s specific thickness. A rule of thumb is to always select a smaller diameter rod because it gives more control on the heat input and lowers the risk of burn through and warping. Also, make sure you’re choosing an ally for the rod according to your metal type (aluminum, stainless steel or mild steel), since each type needs a different alloy to create strong and durable welds.

Rods with low heat input and lower spatter work well for thin metal, as they also lower the chance of damaging the material. It’s also important to choose a rod that results in consistent welds and good arc stability, which leads to cleaner finishes. The use of flux-coated rods, which help prevent contamination and improve weld quality, are also advantageous when working with thin materials.

Frequently Asked Questions (FAQ)

- How do I choose a welding rod for thin metal?

For thin metals, a 3/32″ or 1/16″ diameter welding rod is usually the best choice.

- Can I use a regular welding rod on thin material?

You can use standard rods, but it’s best to use a rod designed for thin metals to minimize burn-through and provide smooth welds.

- What type of welding rod to use for aluminum?

When it comes to thin aluminum welding, the ARCCAPTAIN Aluminum TIG Welding Rod is an excellent option.

- How do I avoid burn-through on thin metal welding?

Using a rod designed for low heat input and keeping a check on the welding amperage used can help avoid burn-through.

- Can you use stick rods on thin metal?

Yes, stick rods such as the YESWELDER E7018 will work on thin metal; especially steel.

- What is the best welding rod for stainless steel?

The very best filler rod choice for thin stainless steel is YESWELDER Stainless Steel TIG Welding Rod.

- How can I prevent spattering too much?

A high-quality rod with stable weld characteristics and a machine-learned arc with a less aggressive profile helps to reduce spatter as well.

Conclusion

Final thoughts on welding thin metals; All of the rods we’ve covered are great options for creating precise, strong, and clean welds. There are unique features about each rod, for example aluminum or stainless steel or for mild steel. Optimal for thin aluminum are the ARC CAPTAIN Aluminum TIG Welding Rod, while SÜA Aluminum E4043 and YESWELDER E7018 offer perfect performance for aluminum alloys and mild steel respectively ensure enough fill for any joint with a decreased risk of burn-through and a flawless finish. The best welding rod for thin metal will ultimately depend on the specifics of your project, including the type of metal and the welding process used, but all of these options are strong and durable for thin application.