Brazing is an ingenious process that operates in the middle ground between the high-temperature extremes of welding and the low strength of soldering in metal joining. Brazing is a metal joining process where a filler metal is heated to a temperature above a specific temperature (generally 840°F (450°C)) and is below the melting point of the base materials. The fine-tuning of contact time permits the generation of tough, seam-free, and decorative joints without impacting the inner structure of the parent metals. This renders it a favored approach across various sectors from HVAC and plumbing to automotive and aerospace, all the way to electronics manufacturing.

The applications are endless, from complex jewelry and assembling fragile medical devices to building strong heat exchangers and connecting vital pieces in aircraft engines. But the success of any brazing operation is inextricably tied to the choice of the brazing rod, the consumable filler metal that flows into the bond to form the joint. A brazing rod may seem like an intermediary of a metallic nature; however, this has proven to be the most vital parameter that influences the mechanical strength, corrosion resistance, electrical conductivity, high-temperature performance, and high-pressure resistance of the joint. The wrong brazing rod selection can cause parts to fail catastrophically, perform poorly, or require costly rework.

Objective of this Guide: The objective of this comprehensive guide is to equip you with all the knowledge required to understand the essential information regarding brazing rods, allowing you to make informed decisions and achieve the best possible results with brazing. We will look at many different brazing rod types and their properties focusing on the material they are made from, how they perform, and where they’re applicable. We will cover everything from the most popular copper-based alloys to the specialized silver-bearing rods so you have a complete understanding of the choices available and are better prepared to make a decision on the right rod for your application.

1) Vouyar Brazing Rod

Within this category, a core selection is the basic 40 Sticks Copper Brazing Rod. Made typically of a copper-zinc alloy, with a small amount of tin to give better fluidity, this is the workhorse rod in HVAC, plumbing, and general repair applications. The relative affordability and ease of use make it popular for joining copper pipes, fittings, and other components. The 40 in the name doesn’t correspond directly to a specific PSI strength rating, but it’s just a guideline that the waders should be best for medium-strength joints. The tensile strength is usually around 40,000 PSI, which is suitable for many plumbing and light structural applications. However, it should be noted that the ultimate tensile strength will depend on the alloy composition and brazing methods. Always refer to the manufacturer’s specifications for specific mechanical properties and operating temperatures for this type of rod. With this type of rod, flux is typically needed to get the best results, cleaning the base metals and promoting good wetting.

2) BLUEFIRE Brazing Welding Rods

Silver-bearing brazing rods offer the best solution for applications requiring greater integrity in joints, better corrosion resistance, and higher mechanical properties. The incorporation of silver within a copper-based alloy matrix leads to considerable enhancement in a number of parameters. The Silver Solder Copper Phosphor Brazing Welding Rods will fix those leaks, and this is a huge improvement. The use of silver, which can vary from 2% to 56% depending on the alloy, enhances wetting action, allowing the molten filler metal to flow readily into and fill tight clearances with really good capillary action. This leads to denser, more cohesive joints with a reduced number of voids and inclusions. Additionally, Phosphorus works as a deoxidizer, which further improves the brazing process and aids in corrosion resistance. Tensile strengths with silver-bearing rods can often exceed 60,000 PSI, while some high-caliber alloys can be rated up in the 80,000 PSI range or higher, making them ideal for mission-critical applications where the integrity of the structure is vital. That is why these rods are used in refrigeration, electrical devices, automobile assembly, and even medical equipment, which call for reliability and a long life. When selecting a silver range, it is best to find the proper content; More silver content means better flow and higher strength but also cost.

3) Tandefio Brazing Alloys Flat Welding Rods

Taking tailored brazing solutions to the next level, Vlad International boasts of its Silver Solder Phos Copper Brazing Alloys Flat Welding Rods with a profile customized for specific joint configurations and brazing processes. The flat rod shapes provide better control of the filler metal deposit, especially in lap joints and other situations where control is important. This design also facilitates a more extensive heat transfer area, which can translate to lower brazing times. These rods are normally composed of an alloy of silver, copper, and phosphorus, which provides good tensile strength, fluidity and ability to resist corrosion. In addition to offering application control, though, a flat profile produces even heating and mitigates the potential for melting of the base metal — a frequent concern when brazing thin or heat-sensitive materials. Applications range from heat exchangers to thin-walled tubing to complex assemblies, where the exact placement of filler metal is critical.

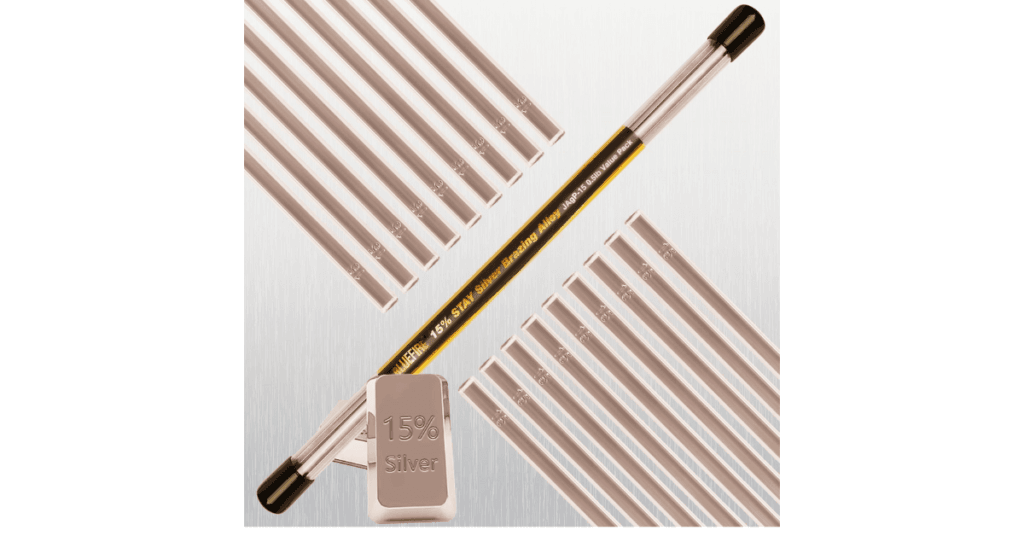

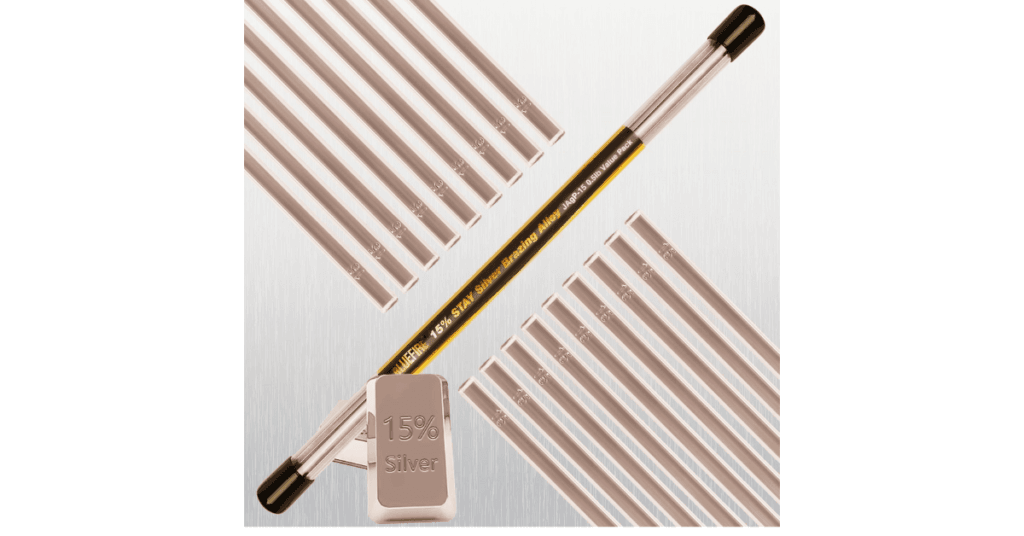

4) Fox Alloy Silver Phos Soldering Rods

If you want to get into an even more specialized alloy, Copper Sticks JAgP-15 Silver Phos Soldering Rods is a good example of specialized brazing rods in such a way that is more customized. The nomenclature JAgP-15 refers to a standardized composition of silver alloy in the industry, where the 15 commonly denotes a silver content of around 15%. Designed specifically for copper-to-copper (and often copper alloys) joining applications requiring high strength and good electrical conductivity. The silver content provides the required strength and wetting action, and the copper matrix provides very low electrical resistance. Phosphorus works as a fluxing agent on copper, making the brazing operation simple and minimizing the need to apply external flux. A major advantage of this self-fluxing characteristic is seen with automated brazing in environments where flux application is difficult or cannot be performed at all. JAgP-15 finds applications in electrical connectors, busbars, and other high-current carrying components in electrical equipment and power distribution systems. It has moderate silver, making it more cost-effective than a higher-silver alloy, yet providing the performance characteristics you need.

5) BLUEFIRE Copper Phosphor Alloys Welding Rods

Lastly, Copper Phosphor alloy welding Rods fall on the lower end of the brazing scale. These rods are made with copper and phosphorus and contain little to no silver. Though not as strong and not corrosion-resistant like silver-bearing alloys, they are relatively inexpensive and suitable for applications with low demands. When used to braze copper to copper, the phosphorus itself is a self-fluxing agent, making the job much easier with no need to apply flux separately. However, these rods typically should not be used for brazing other metals (like steel) or brass unless you have the right flux. Such copper-phosphorus alloys have favorable fluidity and are ideal for filling larger gaps. Typical uses are for plumbing repairs, conjunction operations for copper water pipes, and general purpose brazing when high strength is not of particular interest. The tensile strength of these rods typically ranges between 30,000 to 40,000 PSI, offering a viable option for low to medium-stress applications. Without silver, they are an economical option for general-purpose brazing.

Brazing Rod Selection: Choosing the Right One

Brazing rod is not a one-size-fits-all proposition, even the best of them. Choosing the right option depends on careful consideration of multiple parameters like base metal, joint strength, working temperature, and environmental factors. It is necessary to understand these parameters to ensure a strong, dependable, and durable brazed joint. Other important factors include the type of brazing process used, the joint configuration, and relevant industry standards or codes. With all these things in mind, you will surely be able to be more confident in choosing the right brazing rod that will help you get consistent and permanent results in all your brazing work. Disclaimer — You should always consult with qualified welding or brazing professionals to receive recommendations for your specific application.

Conclusion:

Final thoughts on brazing: Doing it the right way requires skills but also a lot of knowledge about the item you are brazing and the importance of the brazing rod. As we have seen the Best brazing rod is not a universal constant but a function of the specific application, the base metals being joined, and the performance characteristics desired. This allows you to probably focus on relevant details such as joint strength, corrosion resistance, electrical conductivity, and operating temperature to either narrow the options or simply pick the one that best matches your project specifications. You should always refer to manufacturer specs, industry standards, and experienced brazing professionals to ensure you are making an informed call. From industry veterans to do-it-yourself innovators, this guide will arm you with the information needed to produce high-performance brazed joints repeatedly—bringing you reliable, long-lasting, and visually appealing results. So grab the right brazing rod, and head toward your next brazing challenge with the confidence that you have the foundation for success.