MIG welding (Metal Inert Gas welding) is a common welding process that utilizes a continuous wire electrode that delivers a weld pool to the weld joint. The right MIG welding wire is crucial for achieving a high-quality, strong, and efficient weld. Using the right welding wire can improve performance and ensure you have a solid weld. This article delves into some of the best MIG welding wires on the market, their important features, and how they serve different welding needs.

What You Need to Know About MIG Welding Wire?

Different materials, sizes, and compositions of MIG welding wires are available, each designed for certain applications. There are two dominant types of MIG welding wire: solid wire and flux-cored wire. Solid wire, like PGN Solid MIG Welding Wire and findmall ER70S-6, is often used for welding clean metals and can run with shielding gas. Plasticine (flux-cored) wire is a type of wire that is filled with flux in the wire, so there is no need for an external shielding gas. The other key aspect of a welding wire is its diameter with 0.023, 0.030, 0.035, and 0.045 inches being the most common options. Thicker wires are for heavy welding, while thinner ones are for precision work.

Top MIG Welding Wires

WeldingCity offers a high-grade composition that is reliable. It is a type of wire used along with shielding gas, usually argon mixed with carbon dioxide, to produce clean and strong welds. This wire is known for its consistency, which leads to fewer tangling and inconsistent arc problems. The two-pack option provides welders with a supply of products for multiple-day welding projects.

WeldingCity provides top-quality MIG wire that is perfect for automotive repairs, construction, or general fabrication. It also provides a smooth arc and very little spatter, which makes the overall process better. At a 0.035-inch diameter, it achieves a compromise between penetration versus deposition rate and has a multitude of applications.

If working with aluminum, a specialized aluminum MIG welding wire is required. Aluminum has a lot of properties that make the conventional gas-tungsten arc welding wire unsuitable for it, like high thermal conductivity, tendency for oxidation, etc. This 0.030 dia MIG aluminum welding wire with 100% argon gas ensures a low porosity volume as well as high-quality results.

The softness of aluminum can be a problem when MIG welding aluminum, as this leads to wire feeding problems. To avoid this, the use of a spool gun is recommended, since it avoids bird-nesting and helps to provide a more consistent feed of the wire. It is a hallmarked wire widely utilized by the automotive manufacturing industry, aerospace, and marine. Aluminum is a common material that can be used in structural components exposed to harsh environments because of its lightweight and corrosion-resistant properties.

Mild steel MIG welding wire is one of the most widely used and for that reason, make sure that your MIG welding machines and wires achieve a strong welded joint. Optimized for good arc stability and low spatter but also has good mechanical properties. This makes it a fantastic option for welders that need thinner or thicker steel.

MIG welding wire can be used with numerous shielding gases, including pure CO₂ and argon-CO₂ mixtures; this is a significant advantage. CO₂ creates a deeper penetration, making it a good choice for structural applications, whereas an argon-CO₂ mix provides smoother weld beads and less spatter. It is often used for fabrication, metal repair, and manufacturing applications.

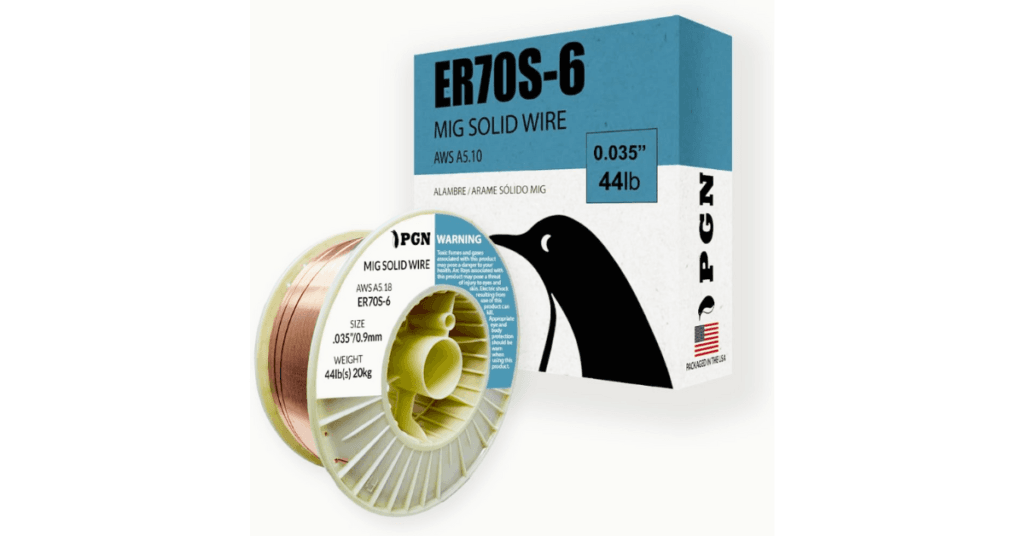

PGN Solid MIG Welding Wire is known for its smooth feedability and high weld quality. The only path that gets you there is the path of how wide the wire is. This wire is made to tolerances and very little variation in diameter leads to a more consistent welding experience. The fabric is of high quality, allowing clean, strong, and long-lasting welds with minimal cleanup afterward.

PGN’s MIG welding wire is specially designed for high-output settings where balanced performance is essential. Varying diameters are available, and the two most popular options are 0.030 and 0.035 inches. This makes the wire perfect for both thin and thick metal sections, thanks to its exceptional arc characteristics.

If you want a high-quality mild steel MIG welding wire with great weld strength and consistency, you can go with findmall ER70S-6. As an ER70S-6 wire, this wire has increased manganese and silicon levels, which help to promote deoxidization and have a positive impact on weld pool fluidity. It results in minimal defects that yield cleaner welds.

TOP SHOT-017-BN top shot black heavy mélange wire structure is a game-changer when it comes to its superior handling of rust, scale, and contaminants compared to other coated mild steel wires. This means that it is perfect for welding applications where surface preparation might not be optimal. This 0.035-inch diameter strikes a decent balance between penetration and deposition rate, making it ideal for medium to heavy-duty welding.

Factors to Consider When Choosing MIG Welding Wire

- Wire Material

The wire material can provide stiff welds. Mild steel wires are the most widely used wires for general welding purposes. For specific applications that demand corrosion resistance and high strength, stainless steel and aluminum wires are utilized.

- Wire Diameter

Wire diameter influences its welding properties. For heavier applications, thicker wires (0.035–0.045 inches) work best, whereas precision welding and thin materials require thinner wires (0.023–0.030 inches).

- Shielding Gas Compatibility

Suitable shielding gas is crucial for MIG welding wires to avoid oxidation and achieve strong welds. Pure CO₂ gives deeper penetration but more spatter, while an argon-CO₂ mix results in smoother welds with less cleanup. Argon is recommended for aluminum welding, at a level of 100%.

- Spool Size and Quantity

If you are engaged in industrial or high-production welding, then select a wire, that comes in larger spools, and helps you mitigate downtime associated with spool changeovers. Brands such as WeldingCity sell multi-packs for extended use.

- Feedability and Arc Stability

A good quality MIG welding wire must display smooth feedability avoiding any wire tangling or bird-nesting. Wires such as the PGN Solid MIG Welding Wire are manufactured to reduce feeding problems and produce constant arc stability.

Conclusion

The application, material you’re welding, and desired weld quality determine the best MIG welding wire for your project. Some brands you might consider include mild steel wire for general welding, aluminum wire for lightweight applications, or a high-performance solid wire that you can use for precision welding, with the options above presenting excellent performance and reliability. Knowing the characteristics of every kind of wire including the feedability, compatibility with shielding gas, and mechanical strength will assist you in choosing the correct one. This is due to the fact that when you use high-quality welding wire you will have better-constructed, longer-lasting weld joints, which all increase overall efficiency and minimize post-weld cleanup.