The process of welding cast iron requires special handling because its high carbon content along with brittleness creates risks of damage to welds if not conducted correctly. For performing durable and long-lasting repairs as well as joints you must choose correct welding rods. Welding rods selection enables a 30% reduction in welding defects which greatly improves both weld strength and overall quality. Many industries crucially depend on precise reliable welds since cast iron is a versatile material commonly found in automotive engine blocks and industrial machinery and pipes.

A weld that uses an improper rod cannot sustain stress making it necessary to either fix or replace it. Understanding special properties and benefits of numerous welding rods used for cast iron requires grasping their designed purposes. This blog provides details about the five most effective welding rods for cast iron to assist you in selecting the ideal match for your venture.

1. ARCCAPTAIN Aluminum TIG Welding Rod

The ARCCAPTAIN Aluminum TIG Welding Rod (ER4043) serves as a powerful welding solution that unites both aluminum and cast iron materials. The rod provides special benefits to cast iron which has made it suitable across different industrial fields including automotive applications as well as rail locomotives and chemical industry and food processing needs. The ER4043 welding rod contains 5% silicon to boost its liquid properties and heat tolerance capabilities. The 5% silicon content in this material makes welding cast iron especially productive because it forms powerful stable weld seams which avoid premature failure even in hostile environments.

The rod dimensions of 3/32″ (2.4mm) in diameter and 16″ (406.4mm) in length make it appropriate for diverse welding tasks and offer excellent control and precision during the process. The welding material operates efficiently with both AC and DC power systems which allows users to choose between multiple power setups. The ideal shielding gas for this rod is 100% argon but helium or mixed gases will execute the task successfully.

Users find that ER4043 rods allow quick and simple use because the welded material produces clean seams while needing minimal cleanup afterwards. The tool operates effectively for welders in both commercial and personal use contexts. The ER4043 rod finds extensive uses in cast iron applications to increase productivity in multiple production sectors.

The ARCCAPTAIN Aluminum TIG Welding Rod ER4043 proves to be an efficient welding tool for cast iron along with cast iron alloys which provides strength and ease of use while serving different applications with versatility.

Specifications:

- 3/32″ diameter and 16″ length

- 5LB package made of ER4043 aluminum

- Compatible with AC/DC power sources

- Requires pure argon or mixed gases for clean, no-cleanup weld seam

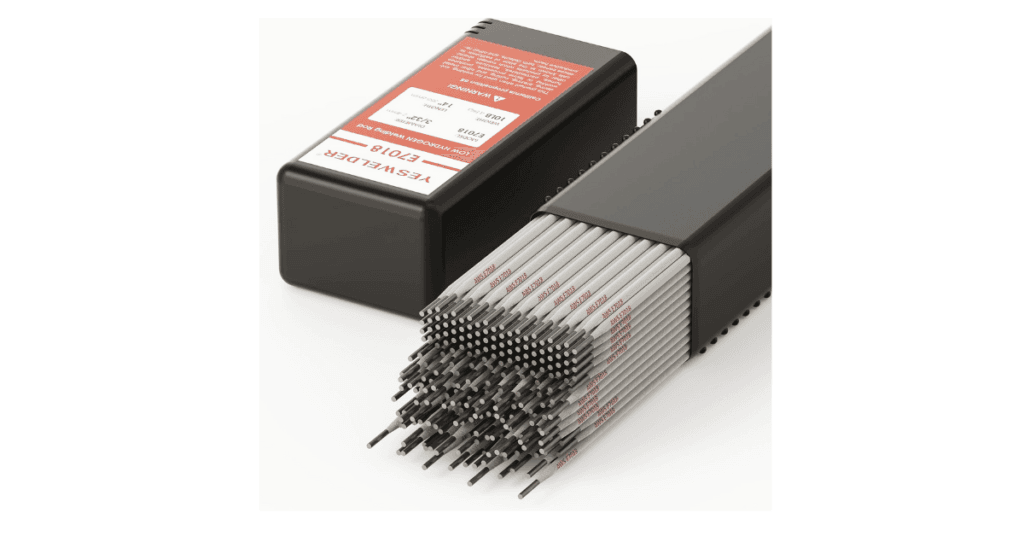

2. YESWELDER E7018 3/32” 10LB Welding Rod

Professionals looking for top-quality low-hydrogen welding performance should consider the YESWELDER E7018 3/32” 10 LB Welding Rod. The iron powder type welding electrode produces excellent x-ray welds that suit various substantial applications including steel structures as well as offshore rig infrastructure and power plant operations. This welding rod maintains peak strength while delivering maximum toughness because it contains low hydrogen levels which support bead integrity. Working with medium and high-carbon steels and cold-rolled steels poses no problems because of this electrode’s design characteristics.

The YESWELDER E7018 offers multiple operation capabilities as its main defining characteristic. The welding rod functions in every fabrication position making it highly dependable for multiple welding applications. The welding rod delivers extraordinary results regardless of your work on flat, horizontal or vertical positions. Welders should utilize this rod to deal with medium-grade carbon steel without preheating requirements and to address challenges posed by cold-rolled steels.

Welders benefit from the E7018 welding rod because it produces a steady arc that delivers low spatter and excellent re-striking capability along with high deposition efficiency for smooth and efficient weld processes. Excellent welding qualities embedded in the rod create a system that reduces defects to ensure smooth professional weld beads.

The E7018 welding rod from YESWELDER finds its main uses in the welding of low-alloy structural steel as well as offshore rig components and power plants and steel structure elements. The rod functions effectively for welding tubular wires when performing initial welds. The rod comes in a protective and durable plastic container which ensures its quality state and safeguards against damage.

Specifications:

- Length: 14”

- Diameter: 3/32”

- Weight: 10LB

- – WS Certified

3. SÜA – Aluminum E4043 Stick Electrode Rod

The SÜA E4043 Stick Electrode Rod functions as a reliable welding solution when working on cast iron pieces including manufacturing, maintenance and restoration work. This rod features special design capacity to weld cast iron materials from sheets, plates, pipes, castings and extrusions having minimum thickness of 3/32″. A dense special extruded layer on the rod stands apart from budget electrodes through hole-free protection by supplying an atmosphere of protective gas which protects the welding arc.

The SÜA E4043 rod functions perfectly for SMAW-stick electrode welding and oxy acetylene brazing because it uses low amperage settings to produce a stable arc with limited spatter and fume emissions. A smooth well-matched color weld with excellent corrosion resistance comes from strong dense porosity-free deposits produced by the rod. Strong weldability characteristics enable professional welders to count on this welding rod because they help with fast arc ignition and re-ignition and easy removal of surface oxides while reducing splatter effects. Made of high-quality materials the rod maintains excellent fluidity through capillaries which promotes efficient welds.

This welding rod has wide industrial applications throughout irrigation, refrigeration, automotive and construction sectors but it can specifically weld boat parts, cast iron door frames, ladders and tanks. Professional welders can effectively use this rod to repair both machining defects and reconstruct extrusions and castings with damaged sections. This flexible tool can be found in three electrode sizes (3/32″, 1/8″, 5/32″) packaged in 0.5 lb, 1 lb, and 2 lb containers for use by cast iron professionals.

- 14-inch length

- Available in 3/32″, 1/8″, and 5/32″ sizes

- You can purchase the SÜA E4043 electrode rod as 0.5 lb, 1 lb and 2 lb packages.

- The metal constructor uses cast iron due to its superior ability to resist corrosion in the manufacturing process.

4. TOOLIOM E6013 Welding Rod

As a low-carbon steel general-purpose electrode, TOOLIOM E6013 helps welders perform different welding tasks effectively. This welding rod maintains outstanding performance levels on short-weld projects conducted at medium depths and provides two-way compatibility between AC and DC welding methods. ALSE 6013 provides dependable welds across multiple positions which helps manage poorly joined metal components made from various types of mild steel. The E6013 rod provides smooth welding performance for a wide range of applications which include thin metal plates, sheet metal as well as pipeline projects and short welding tasks.

Users appreciate the TOOLIOM E6013 because it provides both stable and soft arc performance. The rod maintains its smooth operation through this feature which prevents both smoke and spatter making welding operations more efficient and cleaner. Vertical downward welds create self-cleaning arcs that lead to quick and straightforward starting operations especially during difficult positions. The E6013 rod proves advantageous for welders who need smooth and precise results because it handles sheet metal and cover welding with optimal performance.

The 1/8″ diameter and 14″ length of this welding rod serves many welding purposes and can adjust to welding requirements from 70A to 120A. A plastic storage tube contains the rod for cleanliness and organization that keeps the rod safe from any form of damage.

The TOOLIOM E6013 Welding Rod finds its main uses in welding thin plates as well as pipelines, sheet metal and welding covers. Both commercial and personal welders depend on this rod because of its accurate dimensions, simple handling, and small amount of metal droppings it produces.

Specifications:

- Length: 14”

- Diameter: 1/8”

- Weight: 10LB

- Recommended Amperages: 70A-120A

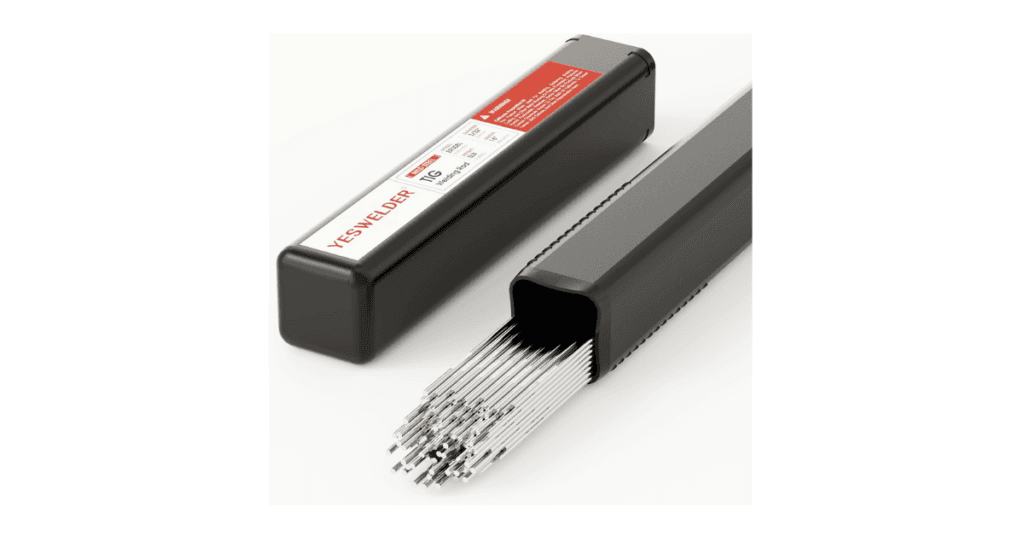

5. YESWELDER Stainless Steel TIG Welding Rod

The YESWELDER ER308L Welding Rod functions as a perfect solution for welding different tasks because it works well in standard projects requiring corrosion protection. The rod stands out due to its minimal carbon content which reaches a maximum of 0.03 percent thus making it perfect for resisting intergranular corrosion. Due to outstanding corrosion resistance properties this rod performs specifically well with cast iron alloys which include 304, 304L, 308, 308L, 321, and 347.

The ER308L rod brings excellent performance in low temperature applications to different industrial sectors through its attribute for cryogenic environments. Manufacturers across petrochemical, pressure vessel and food processing machinery as well as medical equipment utilization make this rod a high-demand industrial component. The weld metal achieves better resistance because of low carbon content making your finished weld more durable in destructive conditions which extends its lifetime.

The best welding outcome requires 100% Argon or a combination of Argon/Helium shielding gas. When Argon and Helium are combined the result creates deep penetration and fast welding speeds which makes this an optimal selection for TIG welding applications. The rod achieves exceptional welding results that lead to precise welding lines while minimizing spatter debris and delivering strong weld strengths throughout the process.

You can find the YESWELDER ER308L Stainless Steel TIG Welding Rod in a 5lb compact package containing rods that are 3/32” diameter and measure 16” long. The durable container provides protection that allows the rods to stay intact from transportation to storage time. The welding rod provides stainless steel professionals and DIY users with a dependable solution for working with stainless components as well as medical equipment and food processing machinery.

Specifications:

- Diameter: 3/32”

- Length: 16”

- Weight: 5lb

- The selective gas material includes pure Argon or a combination of Argon together with Helium.

How to choose a best welding rod? Things to consider while buying

Picking appropriate welding rods remains essential because it directly influences the strength of welds yet depends on various specific project and material-related aspects. The following factors should be taken into account when selecting a welding rod:

1. Material Type: The material type determines the design of the rods which serve either steel or cast iron or aluminum or stainless steel base materials. A suitable rod requires matching characteristics with the substance that needs welding.

2. Rod Size: Welding rods exist in diverse dimensions from different diameters together with different lengths. The selected diameter determines both the amount of amperage the machine needs as well as the depth of weld penetration. To weld thinner materials select rods with a 1/16” or 3/32” diameter whereas thicker materials benefit better from 1/8” or 5/32” diameter rods.

3. Welding Process: Select the proper welding process between MIG, TIG and Stick, and Flux-cored as a selection factor. You need to select a rod from those available since each one operates best with unique welding procedures.

4. Current Type: The rods possess either direct current (DC) or alternating current (AC) compatibility features for welding applications. The stick rod E7018 demonstrates versatility since it operates properly using alternation and direct currents.

5. Coating and Flux: The protective coating of welding rods affects both the stability of the arc during welding and the amount of spatter formation and post-weld cleaning difficulty. Select a rod with an ideal flux according to your welding requirements between smooth welds and rugged welds.

6. Application and Strength:Stress factors along with environmental conditions determine which welding rod suits best. Structural welds, high-tensile welds and components needing corrosion resistance should be considered.

Tips for welding rod maintenance:

These techniques will help you maintain your welding rods in their best operational state:

1. Store Properly:You should store welding rods by placing them in areas free from moisture. You should use sealed containers or rod ovens to store them because moisture will damage their quality by causing poor welds and excessive spatter.

2. Handle with Care:Take a gentle approach toward welding rod handling because carelessness can damage the rod coating. Rotational motion as well as hard handling of welding rods can cause the rod to develop cracks or chips that degrade welding results.

3. Keep Rods Clean:The welding rods should always be inspected for any external contaminants before their scheduled use. A cleaning process using a cloth will prepare them for use. Any foreign substances on the welding rod will result in inadequate weld strength or weld porosity.

4. Use the Right Storage Temperature:The correct storage temperature demands observation for low-hydrogen rods between 250°F to 300°F (121°C to 149°C). Heat control limits both brittleness development and moisture absorption within the flux material.

5. Check Expiry Date:Welding rods particular the flux-coated types lose their quality through time until expiration. The shelf life of your welding rods provided by the manufacturer should be checked before use because expired or improperly stored rods will deliver subpar results.

These suggestions will enhance your welding rod longevity as well as maintain the strength and cleanliness of your welds.

Conclusion:

The selection of an optimal welding rod for cast iron welding depends on three factors: the project materials and welding process type together with the expected strength requirements. All five welding rods that consist of ARCCAPTAIN Aluminum TIG Welding Rod and YESWELDER E7018 and SÜA E4043 and TOOLIOM E6013 and YESWELDER Stainless Steel TIG Welding Rod each provide distinct qualities to suit different welding needs. The welding rods deliver their essential attributes for strong high-quality welds when used with aluminum and stainless steel or cast iron materials. Welding rod performance depends on three critical elements: proper maintenance and appropriate storage conditions and the right selection choice when installing the rod.